The Dawn of Next-Generation Logistics: SKF's Strategic Investment in Chodov

SKF Lubrication Systems CZ is making a significant leap forward in its supply chain capabilities with the construction of a state-of-the-art automated parts warehouse in Chodov. This project, spearheaded by logistics expert Jungheinrich, represents a pivotal shift from conventional manual handling and VNA forklift operations to a highly efficient, automated system designed to support the company's ambitious growth plans. For businesses evaluating future industrial or warehouse space, SKF's commitment to automation in this strategic location offers valuable insights into the demands and advantages of modern logistics infrastructure.

Unpacking the Advanced Features of SKF’s New Facility

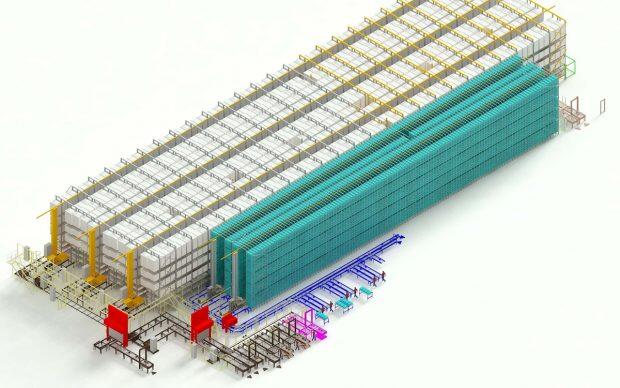

The new warehouse, spanning an impressive 2,700 square meters and reaching a height of 10 meters, is engineered for maximum throughput and precision. It boasts a substantial capacity of 4,800 pallet locations and an additional 31,500 locations for boxes, all utilizing a space-optimizing double-deep storage configuration.

Beyond sheer volume, the facility integrates cutting-edge technology. Key components include advanced rack stacker cranes, a comprehensive conveyor system ensuring seamless material flow, and eight dedicated picking workstations designed to optimize order fulfillment. Robust fire protection systems are also integral to the design, ensuring safety and continuity. At the heart of this complex operation is Jungheinrich's sophisticated Warehouse Management System (WMS), orchestrating every process from inbound goods to outbound shipments with unparalleled accuracy.

A Phased Approach to Uninterrupted Modernization

One of the remarkable aspects of this project is its implementation strategy. The modernization is being carried out in two distinct phases, crucially without interrupting ongoing operations. The box warehouse is slated for commissioning in May 2026, followed by the pallet warehouse approximately a year later in May 2027. This phased rollout demonstrates a commitment to operational continuity, a critical consideration for any business planning upgrades or transitions in their logistics infrastructure.

Strategic Growth and the Future of Logistics in the Karlovy Vary Region

SKF's investment in this fully automated warehouse is more than just an operational upgrade; it's a strategic foundation for planned growth in the coming years. By enhancing efficiency, accuracy, and scalability, the facility positions SKF Lubrication Systems CZ to meet increasing market demands and reinforce its competitive edge. This development also highlights the growing attractiveness of locations like Chodov, near Karlovy Vary, as hubs for advanced manufacturing and logistics operations within the Czech Republic. For companies considering industrial or logistics space for rent, this project underscores the region's capacity for accommodating state-of-the-art facilities and its potential for fostering business expansion. It signals a robust trend towards automation and intelligent solutions in supply chain management, indicating what forward-thinking businesses should look for in their next location.

Source: systemylogistiky.cz